What is EDM?

EDM, Electrical Discharge Machining, is a non-traditional machining process that uses finely controlled arcs to remove metal. The cutting electrode can be any shape and made from any electrically conductive material. Typically the electrode is graphite, brass, copper, or tungsten. The technology has been around since the 1950's and earlier. It has long been a proven method of precision machining of metals and electrically conductive materials. The EDM process is used when conventional machining methods are not practical such as cutting hardened or difficult to machine alloys or machining intricate internal shapes.

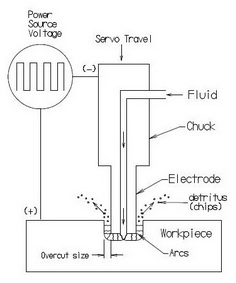

The most common EDM type is called a sinker. It is similar to a drill press with a traveling quill that moves up and down. In most cases the electrode is not spinning but only advances into the work. As the electrode is advanced and gets very close to the work a highly focused electric arc is produced again and again at a high frequency between the electrode and the work. Each tiny arc creates a tiny puddle of liquid metal. When the arc ends the metal liquid is cooled very quickly by the dielectric fluid, contracts and liberates itself from the parent metal and floats away in the dielectric fluid. This process continues and the electrode is advanced as the work-piece wears away. The cavity left in the work-piece is a very precise size that is slightly larger (called the overcut and is usually a few thousands inch/side) and the same shape as the electrode (the electrode could be square or hexagon for example). The electrode usually has a small hole down its center where the dielectric fluid is pumped through the electrode and to the arc gap. This fluid hole will leave a core of work-piece sticking up as with a hole saw.

The AGB Portable EDM uses a nonflammable water-soluble dielectric fluid. This creates an excellent medium for burning holes portably without creating a fire hazard or damaging the surrounding surface areas.

One of the big advantages of using the AGB Portable EDM machine is it's portability. Portability allows one to take the machine to the work and do the hole making or stud extraction work in place. Without the Portable EDM, broken bolts or taps may require removal of the engine head or block in a car or truck in order to extract the broken piece. Additionally, the AGB Portable EDM machine will work in any directions, ie, upside down or horizontally, etc. Most EDM machines are not portable and require that the work be taken to the machine.